Joe H

Board Donor-

Posts

153 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Everything posted by Joe H

-

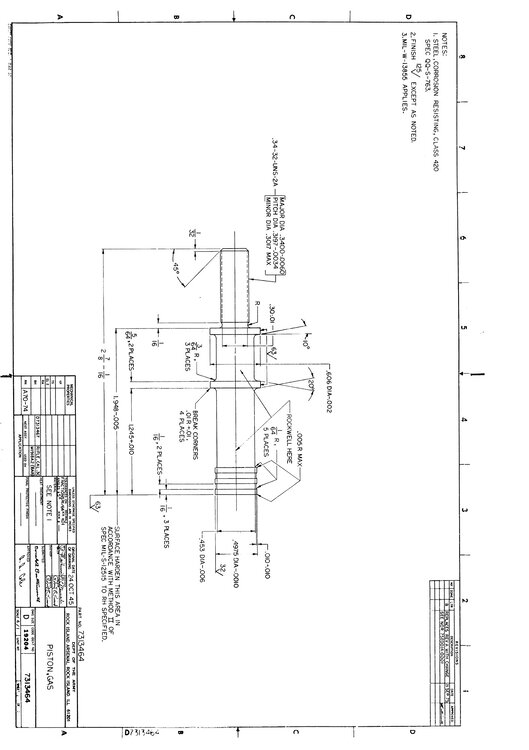

Thread size of the gas piston

Joe H replied to deerslayer's topic in Browning Message Board (Full Auto Only)

Good luck finding one of those. Probably have to make one. Shouldnt be too bad since you are just cleaning up some bad threads. It's leaded steel and not heat treated in that aea. Joe -

Thread size of the gas piston

Joe H replied to deerslayer's topic in Browning Message Board (Full Auto Only)

-

Thread size of the gas piston

Joe H replied to deerslayer's topic in Browning Message Board (Full Auto Only)

-

neonelect, The WWII trigger group that has FA (fast) and Slow FA is very similar to the WWi trigger that has fast and semi. The Slow fire is actually semi that is triggered by the actuator in the buttstock. Remove the actuator and spring and the BAR will fire semi on the slow setting. I think you are in Europe so no discussion about semi requirements here in the US. If you can get a copy of "Rock in a Hard Place" by J L Ballou you can see the tigger mechanisms on P 268-270 and P 290 Joe

-

Want to Buy/Build 1918 BAR gun

Joe H replied to Bayrain's topic in Browning Message Board (Semi Only)

I'm pretty sure this is his website: https://www.wwiibarman.com/ -

Want to Buy/Build 1918 BAR gun

Joe H replied to Bayrain's topic in Browning Message Board (Semi Only)

Billy, IBM came up with the "broach" idea during WW II. The broached slot went the whole length of the receiver. It cut through the threads in the rear end. Prior to approval for the full length slot the rear threads were maintained, which involved a lot of specialized hand work. I've attached a pic of the broached threads in the rear of a WWII receiver. I didn't have the budget for broaching so I drilled 4 - 1/8" holes in the corners and milled out the waste, file work in the corners as required. Interior done with long reach tee slot cutter. Rear hole smaller than slot to provide AFT denial for the slide. Luckily I had enough headroom on my WWII war dept tagged Jackson mill. Joe -

Want to Buy/Build 1918 BAR gun

Joe H replied to Bayrain's topic in Browning Message Board (Semi Only)

"I hear about these semi auto builds, not oow, but have never come across blueprints, kits, manuals etc. And I've never seen one online or in person so I will assume they are purely fictitious, made of hopes and dreams". see my post above, not at all fictitious! "What about an 80% type build into an MOR style rifle? No idea what that would need but that could be a good start." What's a MOR build? "If somebody has a manual or directions on a semi build thats not an OOW that would be amazing. I really hope such a thing exists." It doesn't exist If you want to learn how to build a 1918 BAR semi go over to the weapons Guild: https://weaponsguild.com/forum/index.php?board=47.0 Joe -

Want to Buy/Build 1918 BAR gun

Joe H replied to Bayrain's topic in Browning Message Board (Semi Only)

Bayrain, You are looking at a major project. I know, I've done it. The BAR was not designed to be built as a one-off on manual machines but it can be done. Be sure your machinist has a good set of plans for the receiver so he knows what he is getting into. Remember you have to incorporate all the denials required by the AFT so that you are not making a machine gun. You have to provide the machinist with details of the modifications required before he starts work. The gas system will need mods. to work with the semi auto FCG. The PO 80% receiver requires significant machine work and some long reach tooling to get into that deep receiver. The only drawings that I found that were usable for a build is here: https://www.wwiibarman.com/collections/blueprints-drawings-and-technical-items There are many Dwgs floating around the internet, some inaccurate but mostly unusable except for one original 1918 dwg with the receiver on one sheet, accurate, but very difficult to use. The details of the OOW semi patent is attached. Their patent ran out a couple of years ago. You can replicate the OOW FCG with some new parts and parts from an M1 carbine FCG. IMO if you are not capable of doing the work yourself, forget it. Check with OOW and see if they are taking orders as it will be far cheaper in the long run. At one time they offered complete semi receivers to use with your parts kit. Good luck with your project, Joe OHIO ORD PATENT.pdf -

Ivan, IMO it might be much easier at this point to check with Dan Block "Deerslayer" about the availability of an EZ-Pull kit. In addition to the correct springs, you will need to fabricate a polyurethane buffer. Here's a Thread all about The Ez-Pull setup: http://www.machinegunboards.com/forums/index.php?showtopic=18312 Have Fun, Joe

-

Richard, To answer your question, I built a M1 semi with a Phila. Ord. receiver (have a SBR tax stamp) using the TMR-2 barrel. The PO receiver is built to the same specs as the GI M1. All other barrel related parts are M1 GI. Barrel fit up perfectly looks and runs great. The green mountain barrel has the full auto chamber per the GI specs. Only difference I could tell between the Green mountain barrel and a M1 GI barrel is that the Green mountain barrel is button rifled, The GI barrels are cut rifling. The steel as best I can tell is pretty much the modern equivalent of the original barrels, pre-hardened 4140 alloy steel or something similar. Joe

-

George has a full set for sale. They are in an old Govt format but can be converted to PDF by one of the free conversion programs available online. https://www.wwiibarman.com/pages/about-us-and-contact You will find some some receiver Dwgs and a few parts dwgs on line. But none as complete and readable as above. Joe

-

OOW receiver kit barrel installation

Joe H replied to 1bid_1kill's topic in Browning Message Board (Semi Only)

1id, My experience with the Philly Ord receivers and a GI barrel is that wrench tight you will still be short around 15 deg. The filing is evenly distributed around the circumference. I made my own aluminum blocks with a rosin wrap (Al. will mar the finish) for the barrel to fit in my shop vise. Turned the receiver on with a stillson wrench with leather facing. The wrench must be on the very end of the receiver at the barrel. It is very easy to twist the BAR receiver if you are not careful. I left the receiver locking face .008" proud so I could set the headspace after the GI barrel was in place. I don't know how OOW does the headspace on the receivers. Considering all of the above I think j17422 has the right idea. If OOW will do it let them have at it. Once the barrel is in place it will be their problem to make the headspace right and I'm sure they have plenty of experience and equipment to do it. Joe -

OOW receiver kit barrel installation

Joe H replied to 1bid_1kill's topic in Browning Message Board (Semi Only)

1bid, I recently installed a NESA 1944 GI barrel on a semi BAR I had built using a Philly Ord receiver. Tightening the barrel on the receiver I came up maybe 16-20 degrees short of the barrel being in the correct position (wrench tight). Can't remember the exact degrees but using the thread pitch on the barrel I needed to remove about .003" from the barrel shoulder (not the face of the receiver). My newly machined receiver of course had no witness mark so I used the same procedure as a garand barrel using levels on the receiver and the front sight. I used a small swiss file and carefully filed the barrel shoulder till I got the right fit. File and try, didn't take very long. I was afraid to use a lathe because of the small amount of removal. The filing worked well. I would do the same next time. I have a 1952 ROTA barrel and a PO receiver for a future build. Initial fit is same as above. I think I remember a post somewhere indicating my experience is pretty typical of the Ohio Ord fit up. Joe -

Guys, Currently there are two BAR slides on sale on GB (pics below). I've built a semi from a parts kit and have spare slides. The slides I have all match the latest 1918-A2 parts drawing for the slide. None have the cut outs shown below. What are the cut outs on the slides shown below for ? Are they from some 1918 variant? FND? Oops found the answer, one is listed as FND, the other is not. Thanks, Joe

-

I've bought a few from Numrich, same description as jim c 351. Good price, same condition as Jim described. Joe

-

Gambler, Ez pull springs for the Kahr semi have been discussed here on the Board at great length. There have been virtually no complaints about them. To get a set check with "Deerslayer" (Dan Block) here on the Board. Here is recent discussion you may be interested in: http://www.machinegunboards.com/forums/index.php?showtopic=18312&hl=pull Joe

-

1921 Colt Military Thompson Markings (Project Gun).

Joe H replied to MICK1WV's topic in Thompson Submachine Gun Message Board

Michael, To obtain a Thompson semi you currently have 2 choices: Buy one from Kahr . Plenty of info over on the semi-auto section. Build your own using the PO receiver you have ordered. Check out this site: http://www.weaponsguild.com/forum/index.php?board=105.0 If you live in a state that allows NFA short barrel rifles with the proper tax stamp from the ATF you can have the 10.5" barrel on your semi. Under certain circumstances your home built Tommy could be sold. Joe -

Happy Birthday Dan, Anything left of the cake? My two favorites a Tommy & BAR. Joe

-

4WH, If you haven't found out yet they are available from Phila. Ordnance: http://www.philaord.com/ Bob Bower (Phila Ord) posts regularly on the Thompson Forum as "Reconbob". I'm pretty sure he makes them once a year. He just ran a batch so they may well be available from stock. I can tell you they are top quality. There is a good bit of machining to do to them they into a working semi. Joe

-

Jt, The Green Mountain barrels are made to the original military spec. As far as I can tell the only difference is that they are button rifled rather than the cut rifling on the originals. I have one on a M1 semi that I built using a Philly Ord receiver. Fit & runs perfect. Pic attached. I don't know whether Kahr has changed the barrel threading or any problems are related to the usual sloppy Kahr tolerances. See the link below. http://www.machinegunboards.com/forums/index.php?showtopic=17371 Maybe some members who have recently SBR'd their Kahr can chime in. Joe

-

kamree, If remember correctly the slot in the 1928 frame is wider than the 1927A1 so that the FA sear would not fit in the 1927A-1 slot. The other FC parts will fit. When I built a semi I had to plug a portion of the 1928 frame so that the FA sear would not fit in the frame. Just as Deerslayer noted West Hurley started out with a stock of FA parts. For my first Tommy semi auto build I bought the Kahr fire control parts. Since then they have doubled or tripled in price. For my last build I made a new sear, pawl, modified the FA trip and modified the FA trigger assembly. The only part I bought was the dis-connector. Here is how I did the trigger assembly: http://www.weaponsguild.com/forum/index.php?topic=26117.10 Joe

.thumb.jpeg.285aa330e79c0cffcd036204c2632960.jpeg)

.thumb.jpeg.3413017eed383f22f6ba48a04270d831.jpeg)

.thumb.jpeg.21c41299b5bb1c1eac07a21740e7cb65.jpeg)