tgoldie00

Regular Group-

Posts

17 -

Joined

-

Last visited

-

Days Won

1

tgoldie00 last won the day on November 28 2020

tgoldie00 had the most liked content!

About tgoldie00

Profile Information

-

Gender

Male

-

Location

Dayton, OH Area

-

Interests

Milsurp Rifles, Bayonets, Kit, etc.

Water Cooled VWs with 4cyls and tiny turbos

Recreational shooting

Recent Profile Visitors

61 profile views

tgoldie00's Achievements

New Member (1/5)

1

Reputation

-

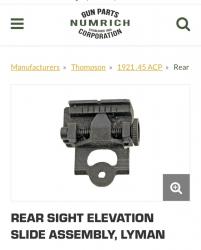

So a twist I havent test seen discussed here with a basic search (though it might be buried in another thread I havent seen). In theory - would the Lyman adjustable rear sight assembly work over the Kahr ladder presently installed? I get the distances may not line up precisely as with a true Lyman assembly. However, as we all know full assemblies are pricey, the laddered assemblies less prohibitive but not cheap - but these assemblies arent the worst thing ever. I am trying to correct some pre-existing left POI and windage adjustment will get me there. Not looking for precision (this issue was with the old Kahr barrel and is consistent with my new SBR barrel - about 3-4in left at 25 yards consistently). Thanks as always!

-

It helped having the Kahr made broken extractor handy. Then it was just remove a tiny bit of material, test fit, compare. Wash, rinse, repeat until the extractor seated. Then I used an empty case to test (outside of the receiver) that it would flex as needed to cycle without any “stickiness” but with as much material on the tab left as possible. Once the above looked good and functioned as designed - into the receiver to check clearances and again, remove tiny amounts of material as necessary till everything moved smoothly and closed as designed. Repeated function testing with snap caps to confirm it would chamber and eject under manual force is as good as I could get until I got to the range. I likely got a bit lucky as a first-timer....hopefully I won’t have to do this again too soon but it’s not THAT bad. I appreciate you chiming in - you reiterated where I needed to be looking so I wasn’t aimlessly making adjustments. Much appreciated sir. ***for anyone attempting - one important thing to note is that due to the difference in size of the recess in the bolt (front near the face) and the tab on the USGI extractor - if material needs to be removed one can’t just remove it only from the front or the back. To maintain the ideal position of the extractor claw one must take a bit off of the front AND the back to get ideal fitment. I had a Kahr extractor (my broken one) as a guide to get the positioning correct. if one removes too much front or back the extractor either will have inadequate purchase on the case rim, or it won’t be able to slip over the rim at all. TAKE YOUR TIME but it can be done! It’s more about patience than skill. That and a good file. ***

-

I mean I would love to make the point that they are actually breaking more than they are fixing by drilling and pinning the extractor at the critical bend point of a spring....and that staking is as or more effective, less labor intensive, and won’t result in the expense of future inevitable factory repairs - but then again I would be writing to the dummy who dreamt that awful repair logic up to begin with so I doubt it would resonate at all...but point well taken none the less! The worst part to me is I am no gunsmith nor do I have any formal training in trades of any kind. I am a bit handy, have the right tools (or will get them), and can follow directions....lol. But I mean seriously. I do understand a bit about how these things work in general and I am mechanically curious - and if I can determine that their repair is just lazy/poor logic and execution - I fear for the qualification of the people in that Kahr shop. Good lord.

-

Well the USGI extractors arrived today. Deerslayer was correct in that there were some initial fitment issues to be dealt with. The Kahr extractor slot at the front of the bolt is indeed rounder and less oblong than the notch on the extractor. I kept the broken Kahr extractor so I was able to file the USGI notch and remove just enough material to get a good and stable fit without it being too tight - just using the Kahr extractor as a template. I also filed a bit of finish and a wee bit of metal off of the top of the tip of the extractor - even when fully and properly seated it looked thicker than the Kahr at the front, and barely cleared the receiver cutout - so just for safety I gave it a bit more room. Once I had tested retention with some brass and felt everything was operating as it should, I staked the rear of the extractor to the bolt. Off to the range I went and everything went swimmingly. Flawless operation over 75 rounds (not a lot but a decent sample to start with). With my newly adjusted ejector brass was flying quite consistently about 10ft to my right and about 1-2 feet forward at the landing point. I feel like this is a good ejection pattern - its consistent and its working. One note that's new - the bolt wasn't holding open on last round fired. I presume this is a result of the EZ pull spring kit perhaps - nothing on the magazine has changed and it was working fine before. If I manually actuate the bolt with the magazine in it locks back no problem. Not a huge concern but if anyone has thoughts on that I am all ears. Before the magazine would not feed the last round but would lock back - now it feeds the last round but doesn't lock on empty. lol Upon return to home a quick inspection yielded no new defects major hardware for the time being - so I think this is - for now - working as I would like it to!

-

I have seen your posts previously about this and am aware. Ill see how things line up and go from there. I can file the new extractor as needed to make it run smoothly. With any luck it will fit. If not - I presume Ill know by actuating the bolt in the receiver and observing interference/drag on the receiver channel? I hone vintage straight razors and have an awesome progression of stones to work with to take tiny amounts of material off and polish with. Im hoping those will be useful (some low grit diamond stones all the way to 20,000 grit polishing synthetics) if I need them. My Kahr is 2014 production.

-

Karl, I have 3 USGI NOS on the way (or they will be in a day or two). I’ll probably do a test fit prior to staking and see how they hold. If it holds great, if not I have a center punch and can make sure that doesn’t move going forward. I’m also not concerned about the drilled hole. Looks to be done well - as dumb of an idea as it was. No cracks apparent.

-

the irony is of course now that I am looking at my pictures again, it was already broken before I went out on the second trip - I just didn't notice. However thinking now USGI extractor perhaps staked to see if it will hold before trying to track down a new bolt. Anyone have pics of some staked extractors so I can see what has been done?

-

Can’t say you’re wrong. I bought this from a friend so at least I didn’t pay full. Lol Do USGI extractors fit? I mean drilling an unnecessary hole, flitting a roll pin to a part unnecessarily aside (I’m guessing this means my bolt is crap - and that this was Kahr’s solution to extractors jumping out).

-

Whelp....fixed one thing, broke another.... Gave the ejector the extra turn it had left in the threads. Went back to the range and it was running like a top for 25 rounds...then a 2 shot burst - then nothing. Before the burst brass was ejecting nicely - good arc and as one would expect. Ugh. Pulled the bolt back and the broken extractor fell to the floor (see pics). Anyone have an extra? Does USGI work in these? Lastly - why the hell would they pin an extractor? Thats just asking for a failure - which is precisely what happened.

-

I have a few issues to iron out and am running out of low hanging fruit. I have some serious ejection/Stovepipe issues. I had them rarely before, and now the issue is every 2-3 rounds or worse. Essentially - the spent case wont eject, or if it does, its not flying much of anywhere (barely jumping out of the receiver and falling straight down). At first I thought perhaps I am oversprung/on weak ammo so I bought the EZ Pull kit. Installed and the problem is now worse (seems counter-intuitive which means my assumptions were wrong). So as I can see it now - the issue is either the extractor, the ejector, or both. Many of the rounds come out of the chamber and the case does an abrupt 180deg rotation and double-feeds with the exit round. Thoughts? Attached a pic of my extractor, and the position of the ejector from the outside (its not flush - but I dont know if this is normal). The extractor seems loose to me - I can move it readily with little effort. Thanks.

-

155 days for a tax stamp and a couple of weeks lead time to work with my preferred local smith for the barrel swap we have a 1928A1 replica from my Kahr 1927A1. Barrel is from Thompson Barrels and is a non-radiussed/finned 10.5in, non-threaded muzzle and the Kahr Cutts/sight re-pinned. The barrel came off with a bit of heat and a good bit of force but it wasnt as bad as either of us anticipated. Having said that I dont think he will be taking these on a regular basis. Lol Will be shooting it tomorrow but it looks great!

-

DARIVS, Thanks for sharing that awesome story of your rifle! I love project guns, especially those that take some time and work to realize to their full potential. This certainly isnt the first, nor will it be the last! I am going to sort through this initial set of hurdles and easy mods to get to SBR and then go from there. I was able to check out barrels today locally and have chosen a black oxide polished barrel of the 1928 variety (polished to match the receiver, color should be dead-on) with fins, non-raduised fins to give it a more authentic and true to form feel. Im keeping the Kahr Cutts Compensator and anticipate that will take a little fitting to make right of course, so I picked the non -threaded barrel to accommodate that. I am fortunate that the stock, wood-wise is pretty nice. Better than you described yours was out of the box. It actually has some nice figure and a couple of coats of BLO so far have started to draw that out. Surprisingly, the horizontal fore-grip Kahr sent me has some lovely vertical striping in it that will look awesome with a little sanding and liberal applications of BLO which is exciting. I love your build execution of the hold-back (my key or third-hand) was awful. It was not to spec and got stuck in the rifle. I had to take material off of all four corners, Stone all four flats, and knock a hair off of the nose to get it to function - which it does now flawlessly (if not awkwardly of course). I will say my 30rd mag and drum thus far have both been flawless. When I took possession of the rifle the drum had a couple of dings on the outside I had to hammer back to flat, and the internal guide-channel fins (Im sure there is a real technical term for those) were bent out of shape in a couple of spots, also easily remedied. In its current form the sights are nearly dead-center at 25 yards, although windage of course would be nice. Ill revisit replacing with a vintage sight (expensive) if that gets worse with the replacement barrel. Im a bit worried that the shorter sight radius might exacerbate the issue (would likely be off 3-4in to the right at 100 yards). If not, Im not dreadfully concerned. The ladder is basically useless to me given how close the aperture is to my eye when up. Planning and parts accumulation to continue while I await the ATFs processing...and overall Im very excited to get this moving in the right direction!

-

All fair points and I have every intention of following the law to the letter - so the insight is appreciated. My career and livelihood depend on that - so if that means I separate a few inches of barrel and relieve them of their original configuration I wont be the one arguing - for sure. It is funny in a way trying to apply modern firearms versus older law, even moreso when interpreting it with a firearm that was part of the original consideration when drafting said laws if not just initially. As you mentioned earlier, there really isnt any tangible recoverable value to the OEM barrel so there is no real sacrifice being made at the end of the day.

-

Im not trying to throw gas on a fire here as Im no BATFE expert for NFA concerns, but my understanding is that if the length is changed of a barrel, that this can be done as long as the applied for length barrel is readily available and that the change is temporary in nature. So semantics - lets put a theoretical case out there. My stamp comes back for the 10.5in barrel and I have the new barrel in-hand. The 16in configuration is then technically the temporary configuration, with the stated barrel in-hand but not yet applied. As I mentioned its all semantics. Also - what if I am present for the modification and am supervising it? Am I fulfilling the requirements? I am not refuting anything being contributed here at all, just adding food for thought. The nature of my work puts me in contact with 3-letter law enforcement officers (not BATFE) on a regular basis and a few are personal friends. We are all NFA junkies generally of the suppressed variety - but often have these debates for fun. The general impression is - as long as the spirit of the law is being observed there isnt necessarily a problem. Anyways..just my thoughts.