Leaderboard

Popular Content

Showing content with the highest reputation since 06/27/24 in all areas

-

The mail man came earlier today and delivered my Thompson. It's not my first machine gun, but it is my first Thompson and I couldn't be more happy about it. I bought the gun from Ohio Ordnance Works back in December. It came to me on a very slow paper Form 4 since I decided to do a C&R transfer. I'd have had the gun many months ago if I'd have had it sent to my dealer and then eForm'd to me ... but oh well. The gun is S-NAC-33 which I've seen briefly referenced in a few books and in some old threads here. I own a lot of guns, but this is certainly the only one with a "famous" (big finger quotes) serial number. 😁 I'm in Virginia and I understand some of these NAC prefix guns went to the Virginia State Police. I'll put in the FOIA request soon and see if I can dig up some details. As a Virginian that would be a really cool connection. I haven't shot the gun yet but I'm planning to rectify that tomorrow.2 points

-

A detail like that instantly catches our eye. But when the wife walks and and asks "Notice anything different?", we got nuthin'.2 points

-

2 points

-

Looks like I will be joining you all at the Thompson Show and Shoot. I am coming in full-on "learning mode", and hope to get a better understanding of the guns and their history. I plan to bring mine along. Looking forward to seeing some of you there!2 points

-

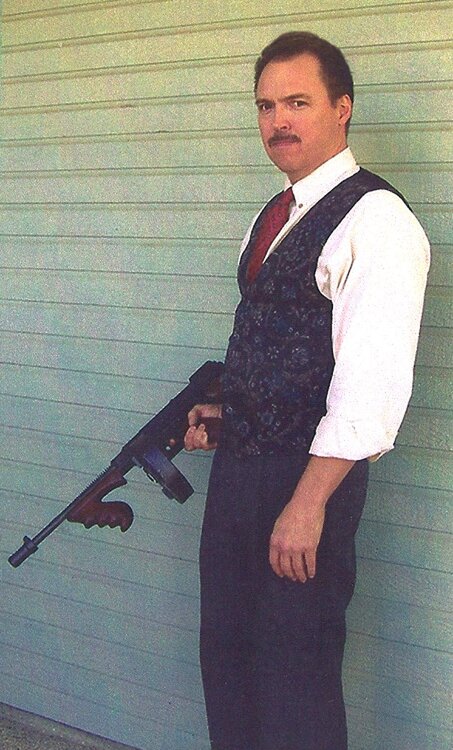

With the production budget at over 100 million, "Public Enemies" had the luxury of filming many of the scenes at or near the original places that the original events took place. Much of the film was shot at multiple locations in my home state of Wisconsin. Madison, Milwaukee, Oshkosh, Beaver Dam, Manitowish Waters. Same thing with locations in Indiana like the Crown Point jail. If the film has the budget, they will go to significant lengths to make it as authentic as possible. I wanted to work on this film and did contact Avy Kaufman casting in NY, but unfortunately I was not as lucky as I was in getting a part in "The Highwaymen". The movie is still very good even though I'm not in it, Ha! But I think that I could have gave Depp a run for his money as Dillinger!2 points

-

Friend of mine calls me up and asks if I wanted to buy a BAR. How can I say no, they are just the coolest! NESA serial nr 59611X. A few questions/concerns though: 1. The receiver has a distinctly red-ish colour. I see no arsenal rebuild stamps, so is this an original finish? Barrel finish is a more "traditional" black/park 2. NEF-stamped parts are NESA, right? 3. The firing pin seems pretty beat up, is this normal? 4. Anything else that sticks out, good or bad? Bipod and grip included but not on the gun. I think I got a fairly good deal but I know pretty little about the BARs. I have another one, a Royal Typewriter, a well. Thanks!2 points

-

James, welcome to the forum. you have been given very good advice from several of our most respected top members on this forum as well as in The American Thompson Association (TATA) and the Thompson Collectors Association (TCA). If you can I would also recommend you attend the All Thompson Show and Shoot in August. Reach out to Tracie Hill and I am sure would welcome you as a late registration. Also if you will let us know where you live ie, what state or region. There are forum members who will reach out to you and assist to do the work that you need done. Do not attempt to remove the barrel yourself or even a gunsmith unless he has the tools to work on a Thompson. If you wanted to replace the barrel and other internals all of that can be done on site at the Show and Shoot in August. I am in Virginia and can easily cover VA, MD, NC etc. Don't be afraid to reach out. Good luck and keep us in the loop on what you decide to do. Semper Fi, Steve aka Sandman19572 points

-

Shoot it. There is no value to the commemorative aspect of this gun, and I dare say there never will be. No one collects them, and it would be worth more if it didn’t have the embellishments. If you are just looking for money, then sell it unfired, but if you have any inclination to keep it and shoot it, don’t worry about devaluing its “commemorativeness.” David2 points

-

Well guys, sad news on the M76 front. I took the part to the machine shop and the price they came back with, even with multiple units was way past the pain point for even the richest of the Forum members. Sorry. So, I did what I should have done from the start and call Andrewski. As usual, he is kind and helpful and is sourcing the part to a friend of his who will make me a unit for a reasonable price. Stay tuned and when I get it back I'll post pics and price.1 point

-

First impressions of the James River Armory (JRA) BM 59 Ital-Paracadutisti. When I open the case (not the best but serviceable) I was impressed by the look of the rifle and that did actual have the detachable tri-compensator and the correctly marked (PC) folding stock. JRA did a very good job of refinishing their parts. The parts are a mix of Beretta made and convert USGI M1 parts (bolt, operating rod, trigger housing and hammer). Speaking of parts the trigger is the correct (marked TA-PC) for the folding stock configuration. I was also surprised to find the operating spring guide rod was installed. There were two things that I was not happy about. One, JRA did not build their receivers with the stripper clip guide. I must admit the stripper clip guide is not a feature that most likely no one use but its presents would make the rifle look more like the real thing. The second thing is the direct fire rifle grenade sight is not correct for the Ital-Paracadutisti and will not operate correctly. I understand the correct sight is impossible to get. I believe the one on the rifle now can be modified to work. Why do I need it to work you ask. I plan to launch practice rifle grenade from it!1 point

-

Hi guys, Just joined to hopefully further my knowledge of the Thompson SMG from the U.K. I have put a deposit on this one in the photos below. The serial reads 228383. It is deactivated but still fully moves/strips etc. I have also got an M1 Carbine and a Colt 1911. Is there anything you can tell me about it from the photos? I have got American Thunder on my watch list. Adam1 point

-

Hello and welcome! I never see before a all matching M1A1, I have one model converted to semi-auto here in Italy but the the lower don't have the same number, as I know M1 and M1A1's all matching are rare to see.1 point

-

If you turn the gun upside down, there should be a small "S" on the receiver, right in front of the magazine well. For "savage", of course. Looks like your gun has HOD WB stamped on the rear left side of the receiver. They look like rebuild stamps, but there is no HOD arsenal that I know of. Could be some kind of British markings. In the USA, sometimes you see police markings, like "LAPD." https://www.coolgunsite.com/pistols/arsenalrebuilds.htm Mine has RIA and FK stamped there. Maybe one of these guys on this site will know. They do seem to know everything!1 point

-

1 point

-

If you want to collect variations, you may find a 3 digit gun interesting. Markings and some features are different from later guns. Ron1 point

-

ONLY grind the front flat tabs (there is a small one and a larger one). Flush with the base.1 point

-

That would be it, I brought several back with me when I visited Germany in 2007. Wasn't really worth all the effort since all they do is light up the retical, no real exciting bells or whistles with this.1 point

-

So, we were rattling off some rounds the other day, and my buddy was loading mags, and he asked me to help him with the drum mag, which... Wasn't taking tension. Now, this was a $169 GunBroker special, so I feared the worst, that the spring had snapped. So tonight, I cracked it open, ready to rivet the spring back together when this greets me on opening the drum up. I guess this one was made on a Friday? At least the spring isn't broken!1 point

-

Not suspect at all. People without money report trouble trying to make lowball offers and are mad when they are rejected. I bought some rare stuff in the last 12 months for a screaming deal. I sent money, they sent product quickly. NOTE. Swedish K/ Suomi mags actually work better than S+W factory mags.1 point

-

it's actually 3 batteries and they are expensive now and they were special order 15 years ago. There were some conversion adapters for sale years ago that did AA batteries that might still be around? Been down that road, not really worth it, but it does work.1 point

-

Chopper, why would you shoot that when the gun is designed for 230 gn .45 ACP. I shoot 230's and my gun runs like a top. Or..... did you just get a killer deal?1 point

-

RIA's August auction has a whole lot of interesting vintage SMGS MP18.1 MP28.2 MP34 MP35/1 EMP MP38 MP40 MP41 Mauser M712 MAB38A MAB38/42 This looks like it could have been someone's collection and about a quarter of a million on the hoof1 point

-

1 point

-

Hi TD., thanks for the info! I purchased several of your books, including Compendium, when I bought this gun in December. I've just submitted my FOIA request online. I did a similar request for my M16A1 a little more than a year ago and I've used the same verbiage for this request. The M16 request didn't turn up anything too earth shattering (my M16 is an otherwise uninteresting Colt commercial gun), but it did dig up some correspondence on cool 1970s Colt Industries letterhead. I'll certainly post whatever history I find on S-NAC-33 here when the request is fulfilled.1 point

-

1 point

-

1 point

-

Well you stumped me! I am a locomotive engineer on long hall and don't recall ever seeing anything like that. It might still be railroad related but I am not running electrified (overhead wire or third rail) territory. It might be signal department also, I just haven't seen one. Working on 38 years now in the field and all over the country, thought maybe you would give me an easy one! Sorry Mike, didn't mean to hijack your thread.1 point

-

1 point

-

Thank you very much, Mark! I might have to pick up a copy of American Thunder for myself. I had no idea that either of those companies were contracted to produce machinegun components during the war. That was my suspicion, as well... though I admittedly have zero expertise in things Colt Thompson. It seems like someone spent an extra couple of minutes on the unmarked trigger. The Stevens has the exact same curve profile on the back side, but the trigger face is "lumpy", as though it were forged into shape, but it missed a step afterwards.1 point

-

jcook119, You are going to have a great time. Caution: The Thompson Show & Shoots are addicting! We look forward to seeing you at this great event.1 point

-

https://youtu.be/p-xS4wfWsXM?si=VBYxDFUNJvbvJCM11 point

-

1 point

-

please use correct part names, you keep saying ejector screw, its extractor screw, incorrect terms get folk confused, , just sayn1 point

-

FWIW ArmaSteel is not "pig iron" It is pearlitic malleable "nodular" iron, similar to what is currently used in many automotive crankshafts, conn rods and similar parts. It's as durable as all hell and is especially good at absorbing vibration. The only downside vs. alloy steel is that it cannot be welded1 point

-

1 point

-

Doug Richardson, as those of us who knew him know, was a Thompson fanatic. He wrote and sold several manuals that he self-published. One of his manuals was "Thompson Submachine Gun Models" ranging from the M1921 Colts up to the M1A1. There are several guns which he refers to as M1922 and M1923 which are guns with longer barrels and bipods. In his manual there are no references and I figured these models were his opinion. I just found a folder with photos of guns he found in museums when he visited Europe going on 40 years ago. Now, how these guns ended up with long barrels and bipods (who did the modifications? when?) and ended up in showcases in museums in Europe is, fascinating in itself. Here is what I found - For starters, here is a photo of a heavy barreled "M1923" Thompson that we have all seen - Here is M1921 Colt #3075 (bipod folded) which according to the note on the back of the photo is/was at the Satory military museum in France. (Sorry - I could not figure out how to rotate the scan to horizontal). Note the stock appears to be the standard stock. Here is M1921 Colt #2594 which according to the note on the photo is/was in a museum in Denmark. Note that the stock is "in-line" and does not drop like the standard stock. And here is a Thompson in a showcase at a museum somewhere in Europe. The label states in English "M1923" and "Thompson", but I do not believe the rest is in English. The serial number is not known. Again, it would be fascinating to know when these guns were made/modified. And how did they survive WW2 and end up in museums in Europe. But the idea seems to have been that Auto-Ordnance was trying to find ways to sell guns back in the 1920's and these model variations were an attempt to do that. Bob1 point

-

All of this is explained in The Thompson Encyclopedia Volume One. Tracie1 point

-

Markings on all imported firearms became mandatory in the 1968 Gun Control Act Effective 10/22/1968. “Section 178.92 also requires licensed importers and licensed manufacturers to conspicuously place the following identification markings on the frame, receiver, or barrel of each firearm imported or manufactured in a manner not susceptible of being readily obliterated, altered, or removed: 3. The name (or recognized abbreviation of same) of the manufacturer and also, when applicable, of the importer;” 5. In the case of an imported firearm, the name of the country in which manufactured and the city and State (or recognized abbreviation thereof) where the importer maintains its place of business.”1 point

-

Rekraps, What is a NAC Thompson? I had the same question when I joined this Board many years ago. It was a subject in which no author had explored with any real depth. After years of research and information from many members of this great forum, I can completely answer your question. And provide much more information on other subjects in the Thompson community. If you want to know about NAC Thompson guns, I recommend my third book, A Thompson Compendium. I guarantee you will not be disappointed. I am away from home at the moment and recommend Amazon.com for fastest delivery.1 point

-

That's the one!!! It has more details in it than anyone could possibly remember without a book. Karl1 point

-

M1 Carbines, Wartime Production, by Craig Riesch (Author) has the nearest to complete description, numeration and detail of any book out there. It can be found at several sources, including Numrich and Amazon. It includes such things as development, production numbers, part variations, manufacturers and manufacturers stamps/codes on every part or accessory available. Of course one should buy the Technical Manual, Tech Order or whatever the Navy called it, that covers not only the M1, but the M2 and the M3. I have several, including one from '45 (I think) that only covers the M1 & M2. The M3 wasn't a thing yet. Another book is War Baby! The U.S. Caliber .30 Carbine, Vol 1, also available from several sources. Parts sources include Apex, as seen above, Numrich, Riverside Armory and many others. Gun shows can be a great source for both literature and GI parts/accessories. V/R Karl, 68coupe1 point

-

So I scored the holy grail of M79 Thumpers! I found an original OEM M79 specific sling! Waiting for the delivery......1 point

-

There is only one “Midas Touch” Thompson, and it was very nicely done. I have handled it up close, and also examined the disassembled parts. I believe the Midas Colt was discussed here, way back. In my opinion, even if you have the last remaining Korean War commemorative West Hurley, it will still be worth less than a regular one. David1 point

-

The Early AO drawing notes the following, with an arrow pointing to teh bottom below the retaining lug "Bend grip here before heat treating to throw forward end up .10" to insure firm seating against barrel" In my opinion, based upon observation, all Colt made parts had the bend, as did parts in all 1928 guns. I think the bend in the milled parts was likely eliminated with the M1, and the subsequent multi part assembled grips mounts did not have the bend.1 point

-

I would not denigrate people who own bumpstocks as people who want to own m16's. They are on the team in favor of NFA items. Yes they are toys, but in today's world our stamped toys,are nothing but toys. We need to keep everyone who believes in all aspects of the 2nd amendment on our side.1 point

-

100% Wrong. the issue was shooting many people without deterrence for a long period of time (supposedly over 10 minutes). The bumpstocks which were not on all the guns had nothing to do with opening fire and having control over a huge crowded area. Fact is, it's possible the erratic fire from bump stocks may have actually saved some people at that distance. Controlled suppressed fire would have resulted in far greater casualty numbers in a scenario like that. Another dramatic failure of government on several levels, once again was to blame for most of it, both long before the shooting began, and into the whole scene. As usual they blame the hammer, and not the guy swinging it. Until this delusion stops, and the mental illness and zero accountability is reigned in, the shootings will continue. In recent times only El Salvador has changed it's methods with dramatic positive results. That will not happen here. We are currently in the midst of celebrating mental illness month? Expect more murders as a result of mental illness, drug usage (including prescription drugs), and moral decline that are all tied together and promoted by certain groups in positions of authority.1 point

-

1 point

-

While the FNC may be military adopted, the Ruger was A-Team adopted, that gets way more points in my book and I love it when a plan comes together Ron1 point

.thumb.jpg.916e8cbf52d177c383b1d2547e718de8.jpg)

.thumb.jpg.659e55976c3b11443034048113727b8f.jpg)

.jpg.537ae9ad741d156d5d25dd1918553080.jpg)

.jpg.00973aaa75319bc5f4f615d8f323dc4b.jpg)

.jpg.05f57425ae5eabf13e92e886f0ab363d.jpg)